Frequently Asked Questions (FAQs)

FIND ANSWERS TO COMMON QUESTIONS

Common questions about the Industrial Management ( IM )

1. Who should study Industrial Management (IM)?

2. I have never heard of IM, is it a new area?

3. What is the different between other disciplines and IM?

4. How is IM similar to other disciplines?

5. What makes IM special from the other disciplines?

6. What are the basic sciences for IM?

7. How do IM benefit society and business?

8. What classes will I take as an IM student?

9. What is the delivery mode in this programme?

10. Are IM only concerned with management?

11. Where do the IM graduates work once they graduate?

12. What is the job scope for an Industrial Engineer/Specialist?

13. How much can Industrial Engineers/Specialist earn?

14. Is the UTAR’s IM programme recognized by any government agency and/or professional body?

15. What is the main different between the Bachelor of Engineering (Honours) Industrial Engineering and Bachelor of Technology (Honours) in Industrial Management programmes that offered by UTAR?

16. What is Work-based Learning (WBL)?

17. What is the difference between WBL and conventional education learning?

18. What are the benefits can students get from WBL?

19. Can the students opt not to participate in WBL?

20. Any criteria set for students to participate in WBL?

21. When the WBL starts and how long?

22. Any allowance given for students during their WBL?

23. Is this a guarantee placement for students to work in the company provided WBL upon graduated?

24. How WBL for IM works? Is it project based or by assessment?

25. If the students opt for WBL path, how many company for students to choose?

26. Why Beckhoff?

27. Is Beckhoff a good platform for students to learn and explore?

1. Who should study Industrial Management (IM)?

Do you like solving problems? Are you interested in how things work? Do you like working with people? Are you an organizer? Do you like working on a team? Does using computers to solve practical problems interest you? Would you like to study a blend of business, management and technical subjects? Are you interested in the way individual parts of a system work together? Are you looking for a challenge? If you answered yes, then you are suitable to study IM.

2. I have never heard of IM, is it a new area?

Yes and No. The UTAR’s IM programme was launched at the year end of 2019 and offered by the Department of Industrial Engineering. Even though IM is relatively new in comparison to other engineering, science and management disciplines, but it is built on a strong foundation of traditions and skills that have been studied for over a hundred years. The first sustained effort in the direction of improved efficiency was made by Frederick Winslow Taylor, an assistant foreman in the Midvale Steel Company, who in the early of 1900s undertook a series of studies to determine whether workers used unnecessary motions and hence too much time in performing operations at a machine. Industrial management also involves studying the performance of machines as well as people. Specialists are employed to keep machines in good working condition and to ensure the quality of their production. The flow of materials through the plant is supervised to ensure that neither workers nor machines are idle. Constant inspection is made to keep output up to standard. Charts are used for recording the accomplishment of both workers and machines and for comparing them with established standards. Careful accounts are kept of the cost of each operation. When a new article is to be manufactured it is given a design that will make it suitable for machine production, and each step in its manufacture is planned, including the machines and materials to be used. The principles of using scientific management have been gradually extended to every department of industry, including office work, financing, manufacturing and marketing. These motivated and make the IM of today.

3. What is the different between other disciplines and IM?

Most of the engineering, science and management disciplines apply skills to a very specific area. For example, Electrical Engineers are concerned with electrical systems and designing circuits, Mechanical Engineers are concerned with mechanical systems and building devices, Chemical Engineers are concerned with chemical systems and explore chemical processes, and Civil Engineers are concerned with physical systems and build structures. However, IM deals with industrial design, management, and application of science & engineering principles to improve the entire industrial infrastructure and industrial processes. IM focuses on the management of industrial processes. Industrial Managers can be said to be responsible for proper and the most efficient interaction of 4Ms: Man, Material, Machine and Method (which every organization needs). A degree in Industrial Management combines the study of engineering, business and management.

4. How is IM similar to other disciplines?

IM take the same foundation courses in mathematics, humanities, and social sciences. In addition, IM also study on Industrial Engineering (IE), Business, and Management courses. Like other engineering disciplines, IM employ mathematical models as a central device for understanding a system.

5. What makes IM special from the other disciplines?

IM is the branch of study which is focused on the creation & management of industrial systems and processes that incorporate people, materials and energy in productive ways. Therefore, IM is a programme that use the knowledge of business, management and technology to efficiently and economically use of the resources to make the organization better and sustain. Training in IM has an emphasis on the varied use of computers, mathematics, and statistics in the field of management. IM is specifically concerned with engineering-oriented industries. IM spans multiple industries from semiconductors and automobiles to plastics processing and metal forging, to oil, cosmetics & food, among others. This area of work involves devising ways & methods to maximize the efficiency of production processes by determining the most economical use of workers, materials, machines, time, capital, energy, and information. IM graduates have been gone through the training in leadership and management during their study. Indirectly, they have higher chances to be promoted to managerial position. In addition, only few universities/institutions offer this discipline in Malaysia. Therefore, if you study IM, you are unique upon graduates.

6. What are the basic sciences for IM?

One of the fundamentals of IM is Scientific Factory Management, which analyses and models production systems and services as queues and entities awaiting intervention from processes to reach a completed product that can function as a consumer good. These queues and entities can be further subdivided into smaller models, which can be visualized in the form of various constraints such as production planning, facilities design, materials handling, manufacturing processes limitations, and job dues. A general solution that integrates these manufacturing aspect with the finance, supply chain and management aspect allows other fundamentals of IM to come into play. Furthermore, this general solution is the gateway to the execution of an effective production systems and services. Hence, a strong background knowledge in IM building blocks will enable wise and accurate decision making when employing tools and software.

7. How do IM benefit society and business?

IM provides a systematic approach to streamlining and improving productivity and efficiency. Benefits that can be linked to IE include:

• Leaner, more efficient, and more profitable business practices while increasing customer service and quality.

• Improved competitiveness, profitability, and reduces resource requirements.

• Setting labor or time standards.

• Increased ability to do more with less.

• Making work safer, faster, easier, and more rewarding.

• Providing a method by which businesses can analyze their processes try to make improvements to them and helps to reduce waste in society.

• Reduce cycle time and increase throughput thus helping more people get their product quicker.

• Assistance in guiding society and business to care more for their workforce.

• Making the world safer through better designed and easier-to-use products.

• Reducing costs associated with new technologies, thus allowing more of the population to better their lives by being able to afford technological advances.

• Efficient and economical use of resources in an organization.

8. What classes will I take as an IM student?

On average, it takes three years to earn a Bachelor’s degree in IM. Typically, the junior years are spent studying basic sciences, mathematics, humanities, social sciences, business administration, marketing, and logistics. During the senior years, most courses will concentrate in industrial engineering and supply chain. IM have broad training in many areas including people-oriented techniques, design-oriented techniques, IE principles, applied engineering, computer techniques, production/industrial planning, scheduling and controlling, supply chain, and management. In addition, the broad learning experience allows students the flexibility to continue toward a Master's degree in Industrial Engineering. Courses in the IM undergraduate curriculum cover the following main focus areas: Industrial Engineering, Management, Planning, and Supply Chain.

9. What is the delivery mode in this programme?

Blended with lectures (theories and knowledge delivery), and practical/laboratory works (skills training and application). Besides, an industrial training for one trimester is also allocated for all students to experience the real working life and environment.

10. Are IM only concerned with management?

No. IM is not only involved in plan and manage efficiently and economically use of all resources in the organization. It also involved in the design of systems and processes to produce and deliver goods and services in all types of organization. IM work to integrate systems involving people, materials, facilities, finances, equipment, energy, and information. The objective is to achieve the best possible results in terms of quality, productivity, cost, and safety. The benefit to you is that there is a huge variety of jobs available for you once you graduate.

11. Where do the IM graduates work once they graduate?

With its diversity, IM graduates appeals to a wide cross section of employers and you will have the opportunity to work in a variety of businesses and organizations. Since it is very similar to Industrial Engineering, therefore the main job for IM graduates is Industrial Engineer/Specialist. Commonly, the IM graduates able to work at the following areas:

• Manufacturing • Business Administration

• Operations Management • Logistics

• Product Testing • Project Management

• QA/QC • Technical Resource

• Retail • Heathcare

12. What is the job scope for an Industrial Engineer/Specialist?

Industrial Engineers/Specialist figure out how to do things better. They make significant contributions to employers by saving money while making the workplace better for fellow workers. One of the main focuses of an Industrial Engineer is to improve the working environments of people – change the workplace while improving the worker. Industrial Engineer measure employee aptitude and motivation to encourage communication, morale, and leadership. Normally, Industrial Engineer will study Japanese management techniques such as Kaizen, Just-in-time delivery, Taguchi methods and Kanban.

13. How much can Industrial Engineers/Specialist earn?

This can be referred to the Industrial Engineering’s FAQ on “How much can Industrial Engineers earn?”.

14. Is the UTAR’s IM programme recognized by any government agency and/or professional body?

Yes. Our programme is approved by Malaysian Qualifications Agency (MQA) and provision accredited by Malaysia Board Of Technologists (MBOT). The UTAR’s IM programme prepares graduates to pursue registration as a Professional Technologist.

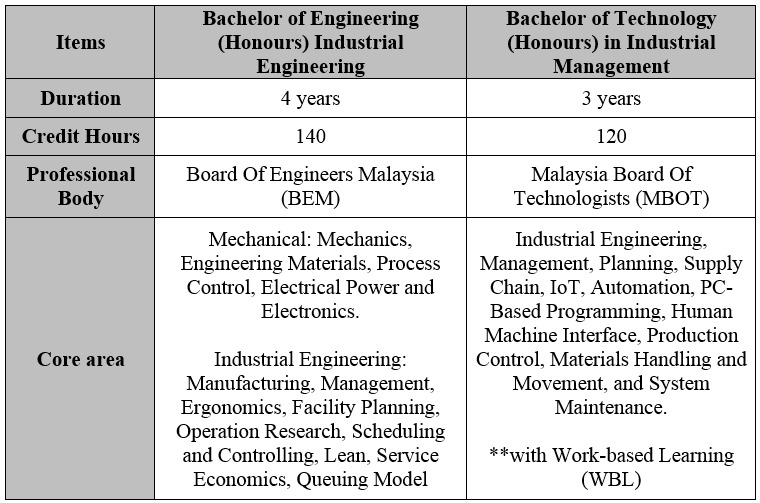

15. What is the main different between the Bachelor of Engineering (Honours) Industrial Engineering and Bachelor of Technology (Honours) in Industrial Management programmes that offered by UTAR?

16. What is Work-based Learning (WBL)?

In today's more competitive world, our economy needs more people in the workplace with higher level skills. Many industries and Higher Education Providers (HEPs) are already working together to achieve this. Work-Based Learning (WBL) as preparation for future employment, wherein a period of work experience in an industrial, commercial or service environment is incorporated into HEP’s courses. WBL is not a new type of activity. It has a long history associated, for example, with various types of apprenticeships. It is also not new within higher education, in so far as areas such as medicine, education, and social work have included WBL as the central element in their programmes for many years. Higher education has always been associated with preparation for work, particularly in relation to entry to the professions.

17. What is the difference between WBL and conventional education learning?

WBL refers specifically to the achievement of ‘planned learning outcomes’ derived from the experience of performing a work role or function. WBL, therefore, differs from conventional education in that it involves conscious reflection on actual experience. That reflection on practice offers an advantage of providing a way in which learners can be supported in structuring their workplace experience to identify their learning from that experience. The term WBL includes a wide range of provision where the focus is on situations in which the main location for the student is the workplace. The teaching pedagogy uses the immediacy of the work context to provide practice and to encourage reflection on real issues leading to meaningful applicable course or programme learning outcomes. WBL provides the reality of an authentic context for learning which produces the currency of transferable credit, enriches student’s learning and creates a well-qualified workforce.

18. What are the benefits can students get from WBL?

STUDENTS have the opportunity to:

- foster learning autonomy, self-development, self-appraisal, and synthesise theory with practice by developing skills of critical reflection;

- develop specialist knowledge, theory and skills by using the workplace as a context for project-based or practice evidenced learning;

- obtain an understanding of employment opportunities and responsibilities through direct on-the-job experience;

- achieve a positive attitude toward work and co-workers as well as improve interpersonal skills resulting from WBL with experienced workers;

- learn, both in class and on-the-job, through significant workplace experiences and able to link academic study and theory to real industrial practice;

- acquire attitudes, skills and knowledge necessary for success in chosen career;

- develop a greater sense of responsibility and work habits necessary for individual maturity and job competency;

- develop employability skills and knowledge that are better taught in the work setting, with minimal loss of personal time or workplace time;

- obtain WBL that can lead to full-time employment for the students after graduation;

- enter the full-time employment market with work experience, thus enhancing chances of success and advancement;

- enhance professional development and future career paths;

- engender ethical understanding and promote ethically aware practice at individual and corporate levels;

- aid progression for students after graduation; and

- be assisted in clarifying career goals and provided a practical means of reaching them.

19. Can the students opt not to participate in WBL?

Yes, in this programme students are allowed to choose either to follow WBL or non-WBL path. For students who opt for non-WBL path, they will follow the conventional education learning system.

20. Any criteria set for students to participate in WBL?

Students need to meet the minimum entry requirement set by UTAR and enrolled in the IM programme. The company may request to conduct interview for student selection.

21. When the WBL starts and how long?

Students will start their WBL (including industrial training) in their third year or final year of study for a duration of one year.

22. Any allowance given for students during their WBL? If yes, how long/ how many months/how much is the allowance provided for students?

It is not a compulsory practice; however, industry normally will provide allowance to students during their WBL duration. The allowance is based on the market trend.

23. Is this a guarantee placement for students to work in the company provided WBL upon graduated?

No. The employment is depending on the company.

24. How WBL for IM works? Is it project based or by assessment?

All the WBL courses are 100% courseworks. Usually, the courseworks consist of assignments/test/quiz/oral presentation/report/project. Courseworks will be used by industry coach to assess students. Course coordinator from University may also involve in giving assessment to students.

25. If the students opt for WBL path, how many company for students to choose?

Currently, Beckhoff Automation Sdn Bhd is the only company that collaborates with FEGT to run this IM WBL programme.

26. Why Beckhoff?

Beckhoff Automation is a German company and its HQ is located at Verl, Germany. Beckhoff uses PC-based control technology to develop open automation systems. Industrial PCs, I/O and fieldbus components, drive technologies, and automation software are all part of the product range. For all sectors, product series are available that can be applied as individual components or combined to form a comprehensive, harmonized control system. Beckhoff’s New Automation Technology contributes to the quality internationally, open control and automation solutions that are used in a wide range of applications, from CNC machine tools to intelligent building automation systems, all over the world. Beckhoff provides global and industry-neutral control and automation systems that are used in a wide range of sectors such as Automotive Industry, Measurement and Testing Technology Industry, Semiconductor Industry, Process Industry, Semiconductor Industry across the world. Industrial PCs, I/O and fieldbus components, drive technologies, and automation software are all components of the product and technology platform.

27. Is Beckhoff a good platform for students to learn and explore?

Yes. Beckhoff committed

to provide practical training and to allow students to work alongside with experienced engineers and technologists in real industry environment to solve industry problem;

to get students ready and competent to contribute as soon as they graduate;

to provide hands-on technological experience that designed towards all related industries especially automation which is a blended approach;

to provide the job opportunities;

to provide understanding of good work culture;

to draft training plans that specify learning goals tailored to individual youth with specific outcomes connected to their learning;

to share resources, engage in online discussions, and participate in live webinars with peers from around the world; and

to provide trainings such as XTS Conveyor System etc.